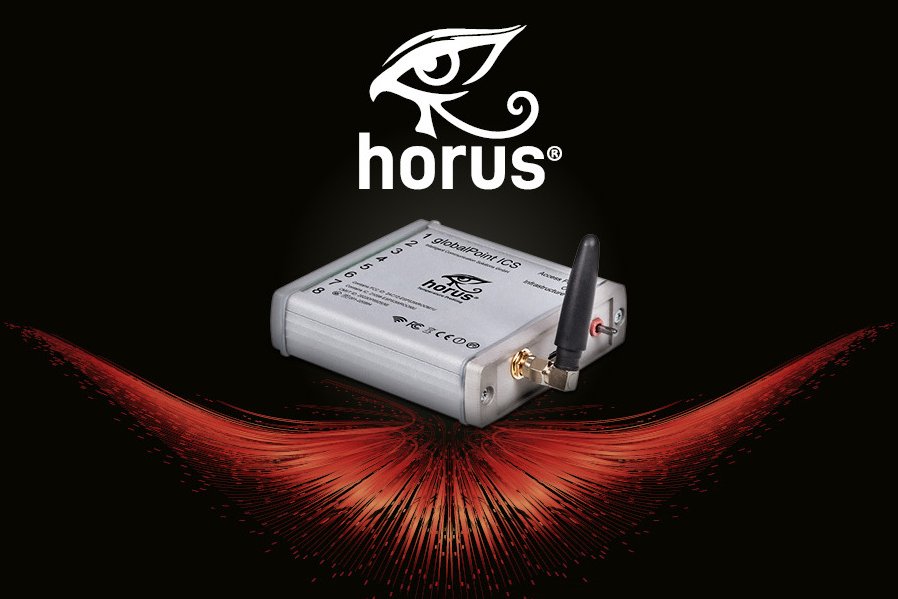

globalPoint horus® profiling

“State of the Art” measuring electronics for fastest profiling

Wertheim/Munich, 2023-11-14

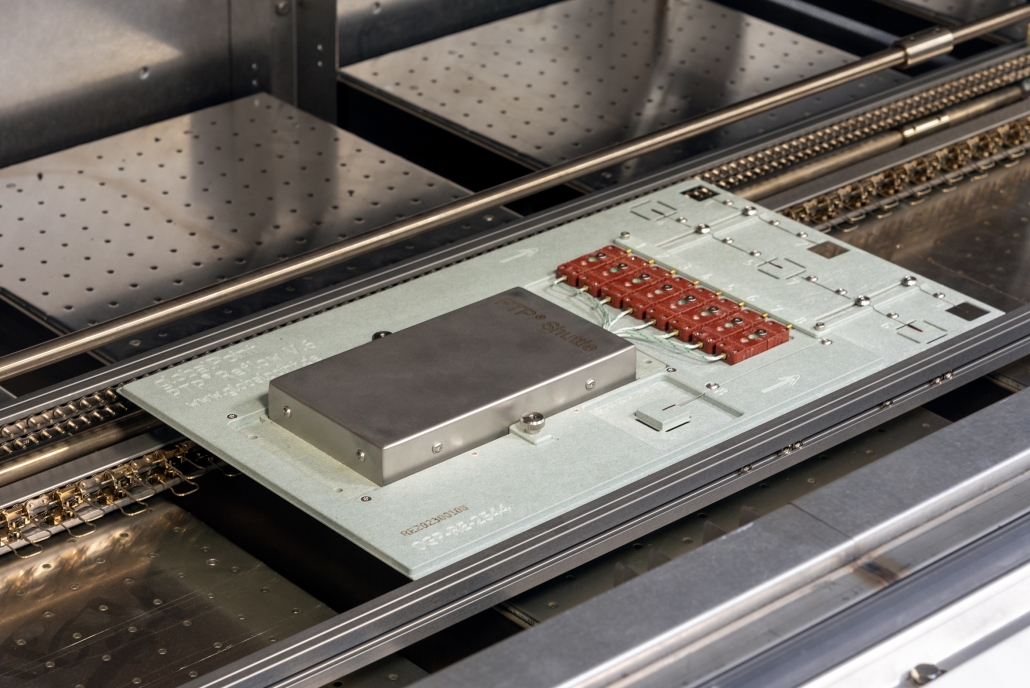

globalPoint develops measuring systems for process recording, analysis and optimization as well as online monitoring in real time. With its precise, innovative measuring electronics and matching measuring boards, including intelligent, user-friendly software, globalPoint has been setting standards for all soldering processes worldwide for more than 25 years. At Productronica in Munich, the renowned specialist for innovative measuring systems will be presenting horus® Professional Temperature Profiling, its new measuring electronics that takes professional solder profiling to the next level and ensures maximum efficiency in electronics production. The time-consuming heating and cooling of a reflow oven during profiling, which can take up to several hours, is now a thing of the past thanks to horus®. With the new globalPoint measurement electronics, it is possible to create a finished soldering profile from the very first profile simulation. If this does not fit perfectly, horus® immediately provides an optimization suggestion.

The integrated autoprofiler can access a whole range of helpful information for its profile simulation. For example, soldering profiles stored in a database can be loaded from assemblies that have already been successfully soldered. Integrated libraries for solder paste and component specifications can be used for support, for example to comply with their limit values. And measurement data can be retrieved from the reflow oven and simulated soldering profiles can be transferred to the soldering system – and vice versa. The good part is that no specialist knowledge is required and even inexperienced employees can be guided through the simulation with assistance.

Access point access – the measuring electronics opens a WIFI hotspot to which the user can then connect. This is particularly helpful if the machine computer with the installed software is not accessible or administrator rights are required to carry out installations. The data can then be easily accessed via a browser – thanks to the responsive design, this is also ideal for mobile devices and WindowsTM 11.

The horus® measurement electronics is suitable for machines from all manufacturers and can transmit the measurement data to a central location in the network. This means that all computers in the network can access it. Of course, only if this is desired. Otherwise, this function can be deactivated. The measuring electronics can be switched on directly on the device using a toggle switch. This ensures that no measurements are forgotten, as the operator does not have to start the software on the computer or on the device first. In all Ersa reflow ovens, horus® Professional Temperature Monitoring will provide perfect data transparency in the future.