horus® Software – Professional solder profile creation

Really smart!

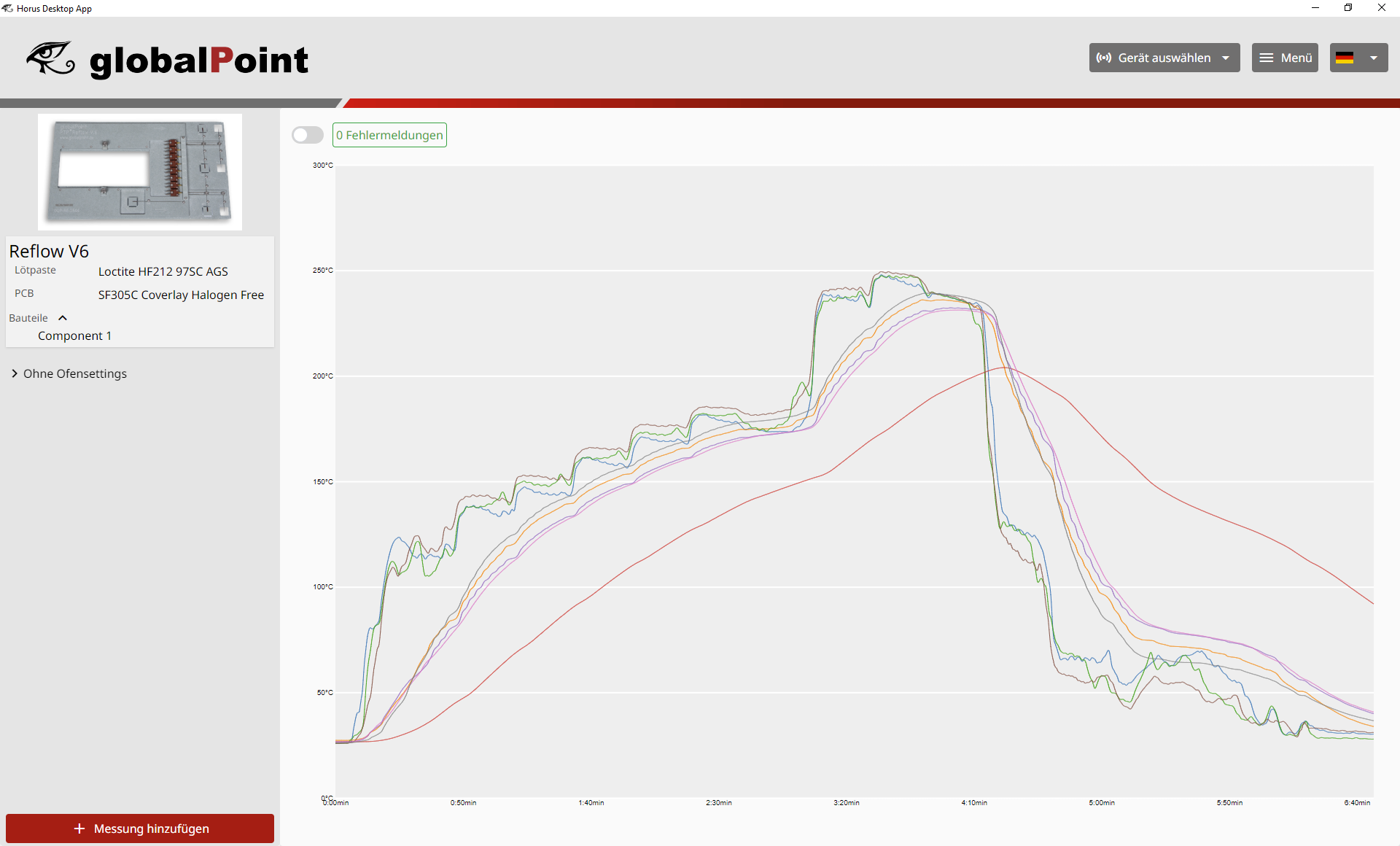

The new horus® measuring electronics takes professional solder profile creation to the next level and ensures maximum efficency in your electronics production. The time-consuming heating up and cooling down of a reflow oven during profiling, which can take up to several hours, is a thing of the past thanks to horus®. With the new state-of-the-art globalPoint measuring electronics, it is possible with the first profile simulation to create a ready-to-use soldering profile. If this does not yet fit perfectly, horus® will immediately deliver an optimization suggestion.

Access point access – state of the art!

The electronic measuring system opens a WIFI hotspot to which the user can then connect. This is particularly helpful if the machine computer with the installed software is not accessible, or administrator rights are required to carry out installations. The data can then be easily accessed via a browser.

| Technical Highlights |

|---|

| Integrated simulation before and optimization suggestions after the temperature measurement quickly lead to the correct temperature profile |

| Database with soldering profiles of already successfully soldered assemblies supports the simulation/profile search |

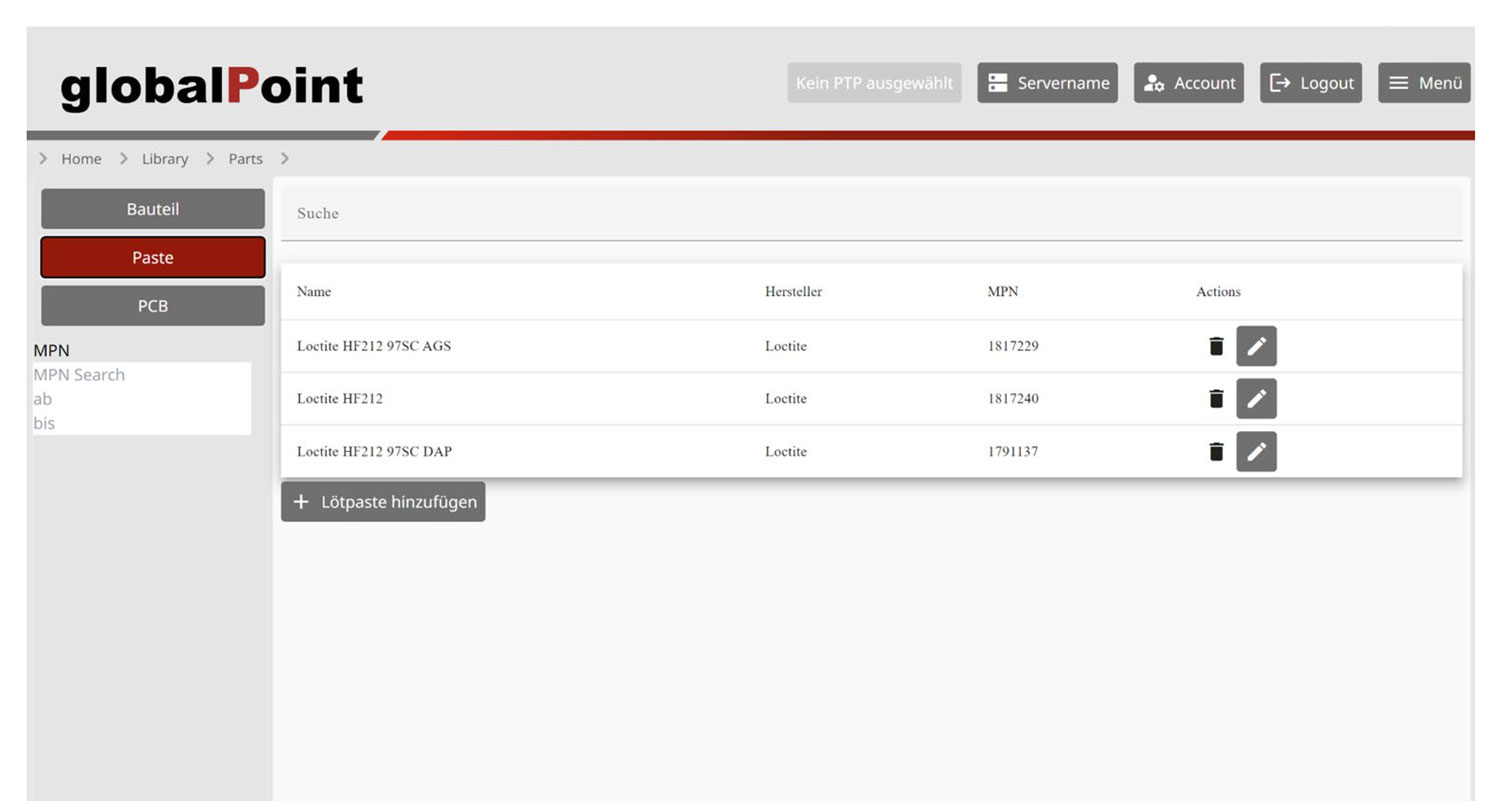

| Libraries for solder pastes and components support the simulation – for example to comply with the limit values |

| Independent WIFI access point (also usable without installation/admin rights) ensures stability and realtime data transmission |

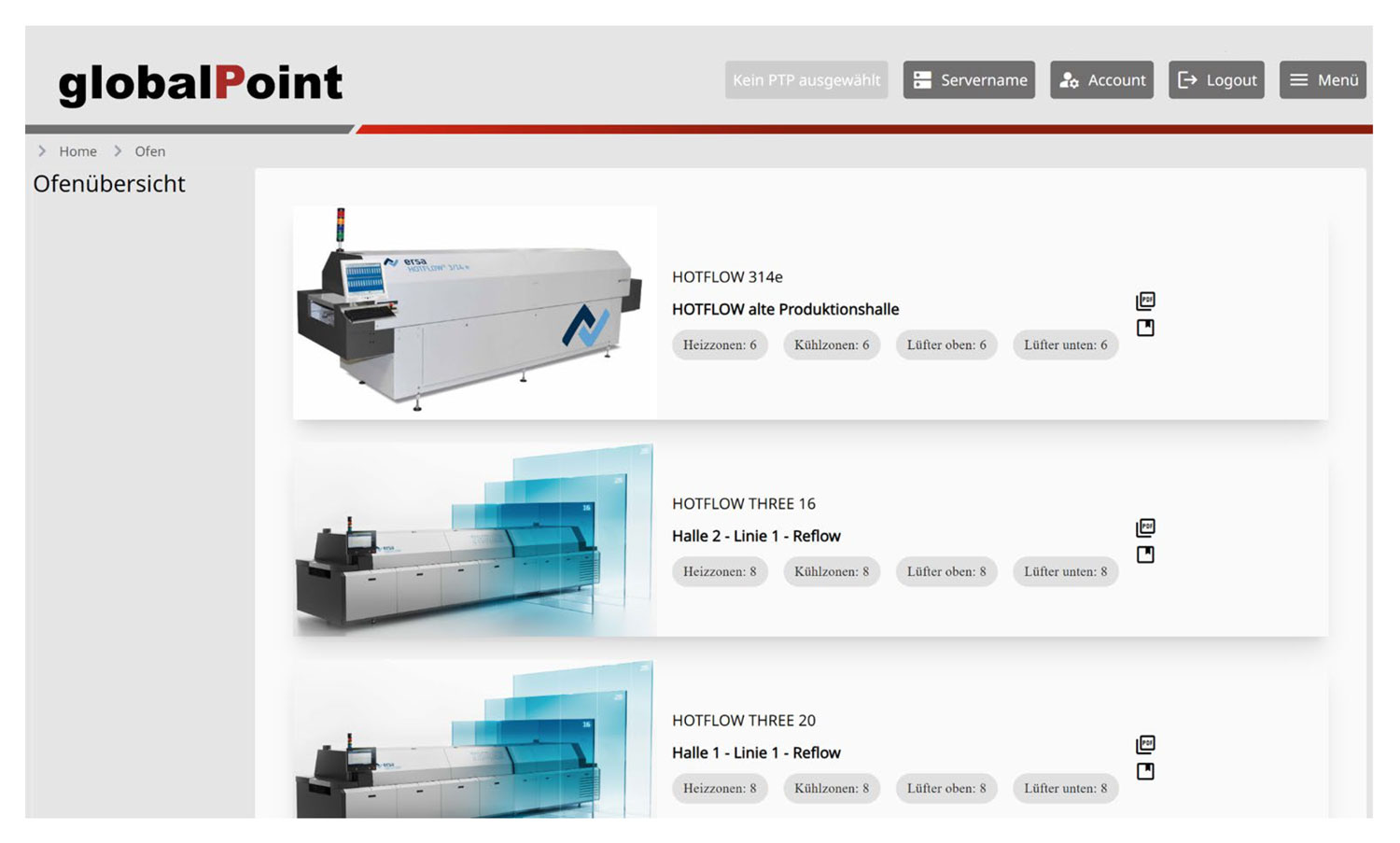

| Interface to the soldering system: Simulated profiles can be transferred to the soldering system and vice versa |

| Suitable for reflow, wave, selective, vacuum and vapor phase soldering |

| Responsive Design |

| WINDOWS 11 ready |

horus® Software – Professional solder profile creation

Really smart!

The new horus® measuring electronics takes professional solder profile creation to the next level and ensures maximum efficency in your electronics production. The time-consuming heating up and cooling down of a reflow oven during profiling, which can take up to several hours, is a thing of the past thanks to horus®. With the new state-of-the-art globalPoint measuring electronics, it is possible with the first profile simulation to create a ready-to-use soldering profile. If this does not yet fit perfectly, horus® will immediately deliver an optimization suggestion.

Access point access – state of the art!

The electronic measuring system opens a WIFI hotspot to which the user can then connect. This is particularly helpful if the machine computer with the installed software is not accessible, or administrator rights are required to carry out installations. The data can then be easily accessed via a browser.

- Technical Highlights

- Integrated simulation before and optimization suggestions after the temperature measurement quickly lead to the correct temperature profile

- Database with soldering profiles of already successfully soldered assemblies supports the simulation/profile search

- Libraries for solder pastes and components support the simulation – for example to comply with the limit values

- Independent WIFI access point (also usable without installation/admin rights) ensures stability and realtime data transmission

- Interface to the soldering system: Simulated profiles can be transferred to the soldering system and vice versa

- Suitable for reflow, wave, selective, vacuum and vapor phase soldering

- Responsive Design

- WINDOWS 11 ready